Industrial Metaverse:

The successor to Industrie4.0?

The Industrial Metaverse comprises diverse technologies and ideas on how companies can improve their production, products and services: Digital twins, simulation programs, VR training or process optimization through artificial intelligence.

As a successor to the initiatives around Industrie4.0, the Industrial Metaverse again offers new opportunities to optimize costs and build new business models.

What is the Industrial Metaverse?

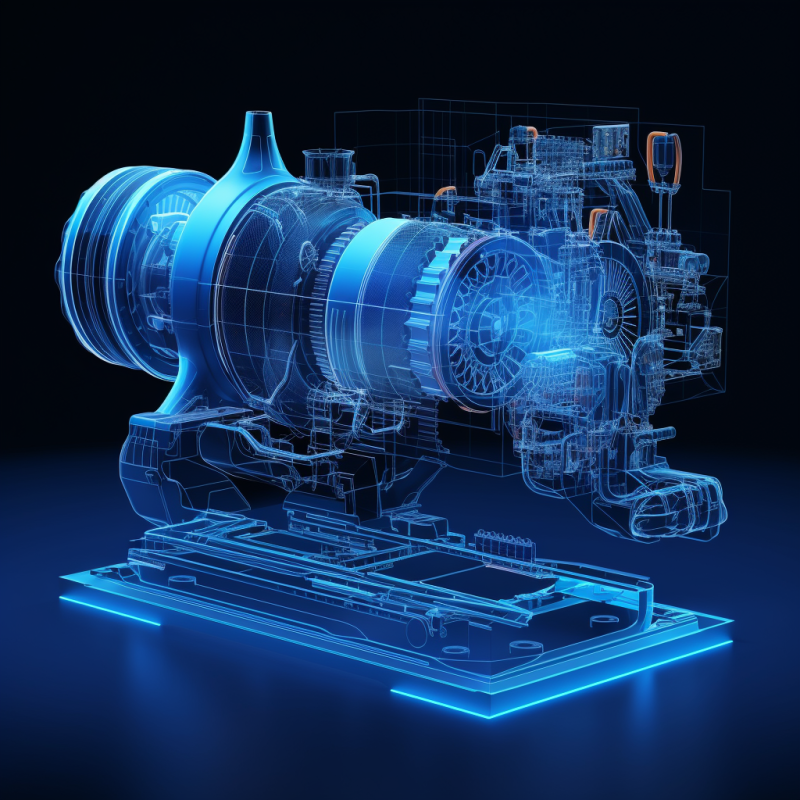

The industrial metaverse is the idea of an immersive space used for industrial applications such as research and development, production, logistics and supply chain management. New technologies such as digital twins, augmented and virtual reality, or artificial intelligence (AI) are expected to optimize processes, services, and products for industrial companies.

The question is: What do you need the Industrial Metaverse for? The Industrial Metaverse is designed to create a more efficient and productive industrial ecosystem between companies, suppliers and customers. It is designed to enable companies to optimize processes and improve their productivity through the use of digital technologies (e.g. artificial intelligence).

To this end, collaboration between employees is to be improved, e.g. through virtual rooms for production development, but also work for the customer, for example through improved aftersales services with augmented reality maintenance.

Increased use of virtual representations and simulations should enable new products to be developed more cost-effectively.

A good example is the development of new products: Before the products have to be built in reality, AI-based simulations fed with real-time data from existing products support engineers and developers in design and conceptualization.

Products can be developed and tested in the digital environment in different configurations without the need to consume costly materials for test products.

What are the advantages of the Industrial Metaverse?

Even though many Industrial Metaverse technologies such as Artificial Intelligence, Digital Twins or AR / VR devices are still at the beginning of their long-term potential, they already offer some advantages for companies today:

1. real-time analysis and control of industrial processes:

Digital twins of production plants enable not only process monitoring but also analyses and various simulations of process variants to improve production processes. Bottlenecks and delays can thus be better anticipated and avoided.

2. development with virtual product simulations:

Trying out new ideas and concepts in a virtual environment will be a relevant lever to save costs in the future. Using digital prototypes saves resources before products are implemented in the real world.

3. improved after-sales analyses:

With Digital Twins of products, companies can better support their customers by performing lifecycle analytics. In this way, problems can be detected at an early stage and appropriate maintenance can be offered (predictive maintenance).

4. VR trainings for further education for employees / career changers:

Training with virtual reality technologies is the future of continuing education for employees. VR training enhances learning and creates a new experience in how content is delivered. Various studies have already shown how much more effective VR training is compared to conventional training. conventional trainings and seminars are.

The Industrial Metaverse is just getting started.

The Industrial Metaverse is still at the beginning of its development. Many companies are analyzing possible use cases and are already implementing initial applications.

But what are typical application examples and use cases for the Industrial Metaverse?

- Use of VR glasses for better visualization of complex products

- Use of AR technologies to support workers/engineers in maintenance/development processes.

- Further education and competence training in virtual simulations for customers and employees

- Engineering processes in virtual simulation for the development of prototypes with different configurations

- Implementation of a digital twin with real-time data to increase efficiency in production processes

These examples are only a small part of the versatile possibilities in the Metaverse. Depending on the industry and company, there are different areas of application.

Companies should analyze early on which Industrial Metaverse technologies they can use to leverage efficiencies or discover new business models.

Your step into the Industrial Metaverse?

Active companies in the industrial metaverse: One Step Ahead?

The metaverse as a future billions market is already captivating many companies. The perspective for new growth motivates to analyze the potentials of the Industrial Metaverse and to make the first steps and investments.

Prominent examples of entry into the Industrial Metaverse abound, including:

BMW’s factory as a digital twin:

BMW started building a digital twin for production facilities at an early stage BMW already uses a software tool for real-time production planning with AI-based simulations. According to the company, this has already created a 20-30% increase in efficiency in planning processes.

Nvidia and the Omniverse:

The graphics processor manufacturer Nvidia is already a permanent fixture in the Industrial Metaverse. With the Omniverse platform, Nvidia supports the development of digital twins and AI-assisted analysis of the data. The software and hardware of this manufacturer can already be found in many projects of this kind.

One of the major collaborations is with Siemens. The vision of the two companies is to further advance the Industrial Metaverse with the use of Digital Twin technology and Artificial Intelligence .

The focus is on the Siemens Xcelerator business platform, as a deployment tool for digital twins, and the Nvidia Omniverse, in which real-time analysis using artificial intelligence is the main feature.

The companies aim to accelerate productivity and process improvements across the entire production and product lifecycle and provide easier access to visually complex and accurate simulations.

Already first showcase cooperation from Siemens

In April 2023, the cooperation of Siemens, Nvidia as well as AWS with FREYR, a Norwegian supplier for battery cells, was presented. Cloud-based digital twins of FREYR factories were created for this company, which is still at the start of its production.

These are designed to help the company make better and faster decisions in its production as well as product design, thereby automating the entire production process.

The Industrial Metaverse for your company?

Even though the metaverse is still in its infancy, companies can already benefit from the new technologies. We support companies in understanding the Industrial Metaverse and its possible applications at an early stage and in taking the necessary steps.

We analyze companies for the effects of the Industrial Metaverse, identify new business models and cost optimizations, and develop a sustainable strategy for your company.